In recent years, the manufacturing industry has witnessed a remarkable transformation with the advent of large 3D printers with high resolution. This revolutionary technology has redefined the way products are designed, prototyped, and manufactured, offering unprecedented capabilities and opportunities for innovation. In this article, we will delve into the profound impact of large 3D printers with high resolution on the manufacturing landscape, exploring their potential and possibilities.

The Evolution of Additive Manufacturing

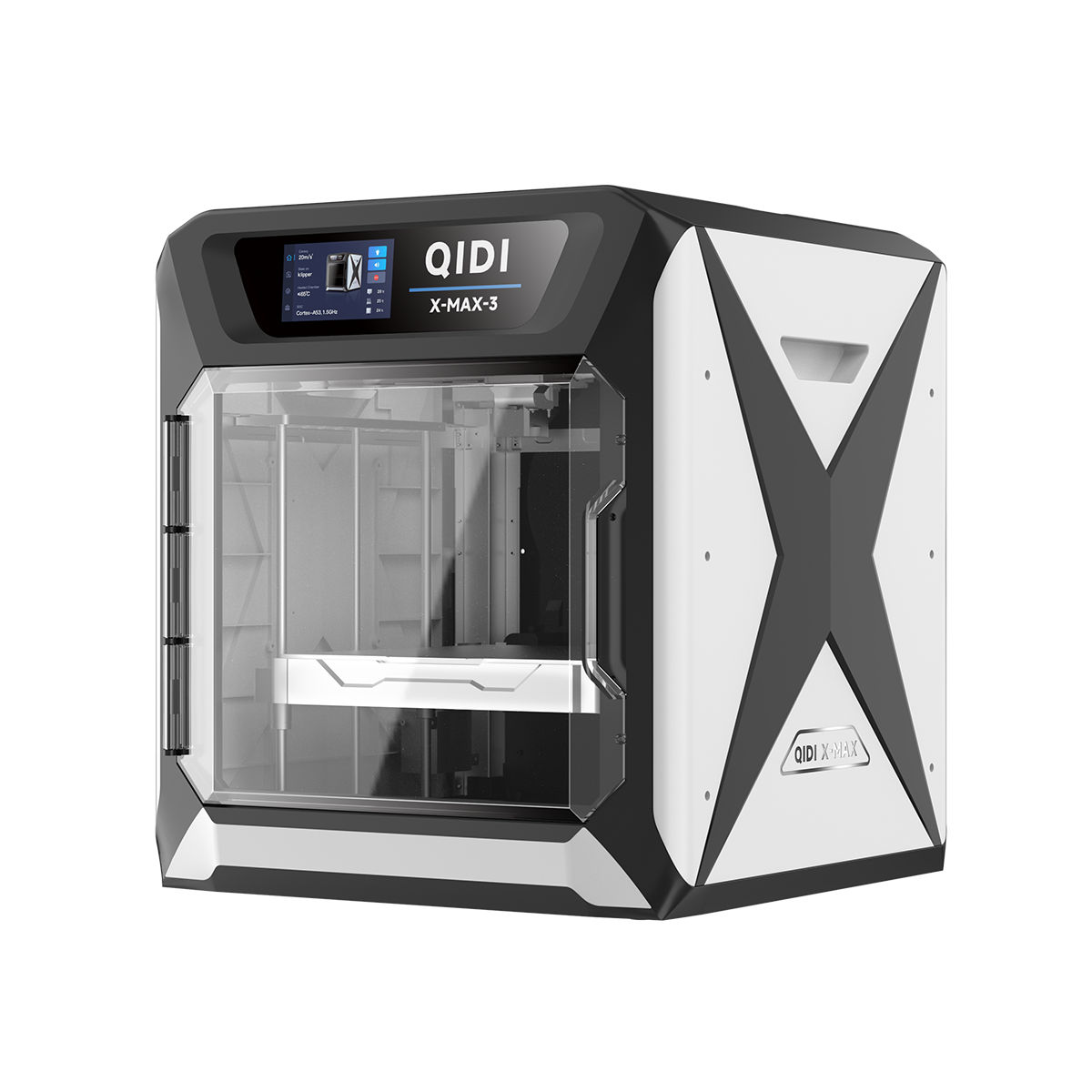

One of the key drivers behind the revolution in manufacturing is the evolution of additive manufacturing, commonly known as 3D printing. This transformative process involves building objects layer by layer, using digital 3D models as blueprints. With the advancement of technology, large 3D printers with high resolution have emerged as game-changers, enabling the production of complex and intricate designs with exceptional precision and detail. The ability to create large-scale components with high resolution has opened up new horizons for various industries, from aerospace and automotive to healthcare and consumer goods.

Unleashing Design Freedom and Customization

Large 3D printers with high resolution have unleashed a new era of design freedom and customization, empowering manufacturers to push the boundaries of creativity and innovation. Unlike traditional manufacturing methods, which often impose limitations on design complexity and customization, 3D printing allows for the production of highly intricate and personalized products. This level of customization is particularly valuable in industries such as medical implants, where each patient's unique anatomy can be catered to with precision, thanks to the high resolution capabilities of large 3D printers.

Enhancing Speed and Efficiency

Another compelling aspect of large 3D printers with high resolution is their ability to enhance speed and efficiency in the manufacturing process. By leveraging advanced printing technologies and high-resolution capabilities, manufacturers can significantly reduce lead times and production costs while maintaining superior quality. The rapid prototyping and on-demand production enabled by large 3D printers have revolutionized the traditional manufacturing workflow, allowing for agile and responsive production cycles that align with the dynamic demands of the market.

Empowering Sustainable Manufacturing

Furthermore, large 3D printers with high resolution are empowering sustainable manufacturing practices by minimizing material waste and energy consumption. The precise and controlled nature of 3D printing processes ensures that only the necessary amount of material is used, eliminating the inefficiencies associated with subtractive manufacturing methods. Additionally, the ability to create lightweight yet durable components contributes to overall energy savings, making 3D printing an environmentally friendly alternative for sustainable production.

In conclusion, the advent of large 3D printers with high resolution has ushered in a new era of possibilities for revolutionizing manufacturing. From unleashing design freedom and customization to enhancing speed, efficiency, and sustainability, the impact of this transformative technology is far-reaching and profound. As we continue to witness the evolution of additive manufacturing, the power of large 3D printers with high resolution will undoubtedly play a pivotal role in shaping the future of the manufacturing industry.