Because of their adaptability and user-friendliness, hot melt adhesive films have been gaining more and more traction in the textile industry in recent years. They provide a variety of benefits, such as superior adhesion, strong bond strength, low-temperature flexibility, and more, which make them ideal for use with fabric and other materials.

Films used for hot melt adhesives are typically made from thermoplastic polymers, which, when heated, turn into a liquid state. They come together to form a bond that is incredibly sturdy and can withstand high temperatures as well as abrasion. In addition, they are not only light and flexible, but also strong enough to withstand the rigors of long-term use without breaking down.

The use of hot melt adhesive films is possible on any type of material or fabric. In addition, hot melt adhesives have exceptional waterproofing properties, which makes them an excellent choice for use in applications that are exposed to the elements, such as boat covers, awnings, tents, and tarps.

Buyers of textile fabrics can enjoy several benefits not available when using traditional glue-based adhesives instead of hot melt adhesive films. When looking for an efficient solution when purchasing textile fabrics, hot melt adhesive films are an excellent option for anyone who combines all of these features into one convenient package.

The Advantages of Using Hot Melt Adhesive Films for Textiles and Why You Should Know About Them

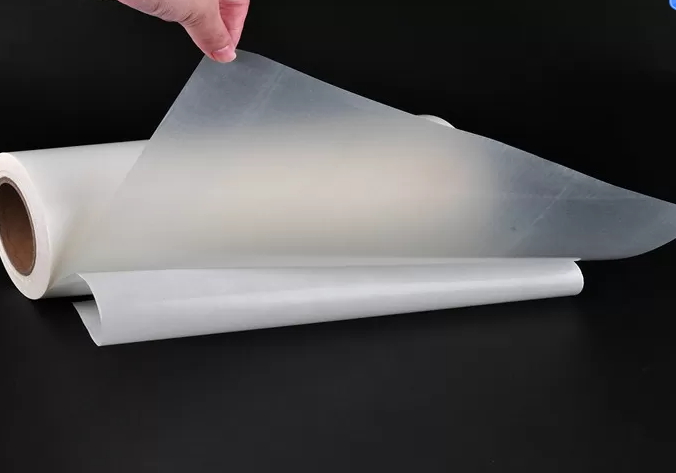

Film with Hot Melt Adhesive for Textile Fabric No. 6145

You've probably heard of hot melt adhesive films in your role as a buyer of fabric. It is a one-of-a-kind answer that possesses the potential to completely transform the way in which one considers textile fabrics. In order to help you make an educated decision regarding the purchase of fabric, we are going to discuss some of the advantages of utilizing hot melt adhesive films in the textile industry in this post of our blog. They are constructed to withstand both high temperatures and prolonged exposure to moisture without causing any damage to the fabric's inherent integrity. In addition, the superior adhesion properties provided by these films ensure that your fabrics will not shift or move in their positions regardless of the environmental factors to which they are subjected. Because of this, they are an excellent option for commercial enterprises that prioritize cost reduction without sacrificing the quality of their output.

In conclusion, hot melt adhesive films have a wide range of applications because of their capacity to form bonds with almost any type of fabric material. These materials include nylon, polyester, cotton, wool, leather, and a great number of other types of fabric. They are also suitable for use on any surface, including wood, metal, stone, glass, plastic, and even paper products, which makes them an excellent choice for a large number of different applications. In addition, these films are available in a variety of sizes, making it possible to locate one that precisely satisfies your requirements regardless of how modest or substantial they may be. The durability and strength offered by these films are unmatched, and in addition, they do not negatively impact the environment and are very affordable. If you are looking for an adhesive solution that provides all of these advantages in addition to others, then you should put Hot Melt Adhesive Films at the very top of your list of potential options.

Instructions for Using Hot Melt Adhesive Film on Textile Fabric

If you are looking for an adhesive solution that not only offers a quick and easy application but also a secure bond, hot melt adhesive thermoplastic adhesive film is an excellent option to consider. However, in order to guarantee the best possible results, it is essential to have a solid understanding of how to correctly apply the hot melt adhesive thermoplastic adhesive film to the textile fabric.

Different kinds of hot-melt adhesive films can be found.

-

There are a number of distinct varieties of hot melt adhesive that can be purchased in today's market

-

Certain films may be more appropriate than others for the material that you will be bonding, and this will determine which films you should use

-

For instance, if you are bonding fabric-based materials like upholstery or clothing, then a polyurethane-based hot melt adhesive film would be an ideal choice due to its flexibility and strength when exposed to changes in temperature or humidity

-

This would be the case if you were bonding the materials

-

It is simple to apply, it provides exceptional adhesion, and it can be utilized in a wide variety of contexts

-

When making your choice, you should think about factors such as the material's ability to withstand high temperatures, its adhesion strength, its elasticity, its resistance to water, and its resistance to chemicals

-

In addition, some formulations are designed specifically for particular end-uses, such as upholstery or apparel, making them more applicable to those particular applications

-

Talk to an experienced representative if you are unsure which product would be best for you so that they can point you in the right direction and help you make an informed decision

When the thermoplastic adhesive film is applied, you want to make sure there aren't any lumps or clumps in it because this could affect how well it performs. Also, check to make sure that it hasn't been kept in a place where it could have been exposed to high temperatures or moisture, as this could also lead to problems when it's being applied.

Think About Your Tools And Equipment.

When using hot melt adhesive films for applications involving textile fabrics, it is essential to give careful consideration to the kind of machinery required for the material to be applied and cured in the correct manner. To ensure that hot melt adhesives are applied correctly and form a strong bond with fabrics and other materials, it is typically necessary to use specialized equipment like heated rollers or applicators. This is the case for the majority of hot melt adhesives. Before you go out and buy a hot melt adhesive film, you need to make sure that your equipment is capable of meeting these requirements first. Only then can you be sure that your application will be successful.

When it comes to adhering textiles and fabrics together, hot melt adhesive films are a fantastic option; however, in order to achieve the results you want from using these products, there are certain best practices that need to be followed when purchasing these products.