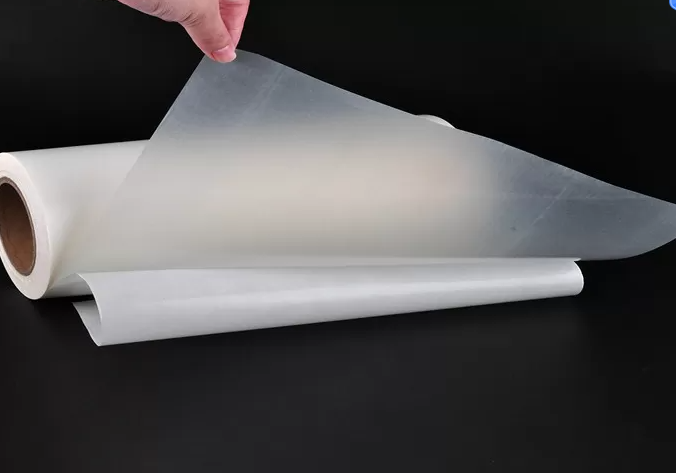

Extruding hot melt adhesive material into a tpu hot melt adhesive film that is both thin and flexible is the first step in the process of making hot tpu hot melt adhesive film adhesive webbing. This material possesses a wide variety of properties, such as resistance to high temperatures, watertightness, adhesion to a variety of substrates, and even flame retardancy. These properties allow this material to be used in a variety of applications. This class of product has great adhesion on a wide range of substrates, from paper and cardboard to steel and plastic, and everything in between; it even works well on things like glass and ceramics. PSA hot melt adhesive webbings are typically used in applications in commercial and industrial settings, and these webbings are put to use for a variety of purposes, including labeling, laminating, and packaging. The ability of this type of product to provide superior adhesion to difficult surfaces such as powder coatings or galvanized metals is the primary benefit that it offers in comparison to the standard PSA version of the product that it offers. This ability allows the product to provide superior adhesion to difficult surfaces. In addition to this, they are able to consistently adhere to a wide variety of substrates in environments that can be either cold or warm, and they provide excellent flame retardancy and chemical resistance when it is required.

Because of this, it is possible to modify them so that they fulfill the prerequisites of a specific application

-

How to Figure Out Which Kind of Hot Melt Adhesive Web Will Be the Most Appropriate for Your SpecificationsHowever, choosing the right kind of hot tpu hot melt adhesive film adhesive web for your particular needs can be a challenging and time-consuming endeavor

-

The use of hot melt adhesive web is a common and cost-effective option for a variety of commercial and industrial applications

-

It is essential that you choose the appropriate hot tpu hot melt adhesive film adhesive web for your project

-

There is such a wide variety of options available on the market that it can be difficult to know which one to pick

-

This article on the blog will provide you with some helpful advice on how to select the hot melt adhesive web that is most appropriate for your specific requirements by guiding you through the process step-by-step

-

Polyolefin, polyurethane, ethylene vinyl acetate (EVA), polyamide, and styrene-butadiene copolymers (SBC) are some of the materials that are frequently used in the production of hot melt adhesive webs

Other materials that may be used include ethylene vinyl acetate (EVA) and polyamide. For instance, webs that are thicker are better able to withstand higher temperatures, while webs that are thinner are better suited for applications that take place at lower temperatures. This is because thicker webs have a greater surface area to volume ratio than thinner webs do. In addition, the formation of a strong bond between certain substrates and adhesives requires the use of specialized adhesives; as a result, you are strongly encouraged to read all of the relevant information before purchasing the product of your choice. It isn't always easy to choose the right hot melt adhesive web, but if you follow these simple tips, you can help ensure that you get the perfect product for all of your particular needs without having to spend an excessive amount of money! Conduct additional research into the many different products that are currently available to buy, as well as a price comparison of the various options made available by the various companies that make those products. By doing so, you will have the assurance of knowing that whichever product you choose to go with will deliver the best possible results without blowing your budget completely out of proportion, giving you the peace of mind you need.

Depending on the specifics of your situation, a hot melt adhesive web might be the best choice for you if you are looking for a method that is both quick and reliable for bonding together materials such as plastics, wood, fabrics, paper, and metals. One of the most significant benefits of using a hot tpu hot melt adhesive film adhesive web as the adhesive is that it only takes a few short minutes before the product is completely dry and ready to be put to use. This advantage can be found in the fact that it only takes a few short minutes. In addition, hot melts can be used to adhere a wide variety of materials to one another, making them an extremely versatile adhesive option. Because of this, neither time nor money will be wasted because it will not be necessary to purchase pricey equipment or additional supplies such as brushes or solvents. This will prevent the loss of both time and money. Last but not least, hot melts offer superior defense against the effects of water damage. This ensures that they will not become brittle or warp when exposed to moisture, both of which are common side effects of using other types of adhesives.

If, however, it does become loose at a later time, you can reheat it using your applicator gun until it becomes softened once more. This can be done until it becomes loose again. If there are any issues, you should be able to quickly fix them without having to start the process from the very beginning thanks to this. Some useful advice for working with hot melt adhesive webThe web of hot adhesive is a versatile material that is capable of bonding a wide variety of materials, including metal as well as plastic and fabric. This is due to the hot tpu hot melt adhesive film adhesive's ability to bond to a wide temperature range. To get started, you have to ensure that the surfaces of whatever materials you're bonding are clean and free of any dirt or debris. This is the first step in the process. This is the most crucial stage of the process. If something like this occurs, the web of hot melt adhesive will produce heat, which will in turn cause the adhesive to evaporate, which will result in an even greater weakening of the bond.