The term "turning" can refer to a number of different processes, each of which is utilized in a different sector of the economy to produce components that are progressively more complex than the ones produced by the previous sector. However, in order to achieve the objectives of the design throughout each stage of these manufacturing processes, it is necessary to carry out their individual step-by-step procedures in their entirety. This is the only way to ensure success. The removal of unwanted material from a workpiece is accomplished through turning operations, which involve rotating the piece along an axis while the piece is being turned. In the process of threading, a tool specifically designed for threading is utilized to cut threads into the exterior surface of a workpiece. The finished product of the process is called a thread, and it is composed of grooves that spiral in a helical pattern and have lengths and pitches that have been predetermined. The lengths and pitches of the grooves are measured in increments. The process of removing material is carried out multiple times until the desired diameter has been accomplished. An operator needs to be familiar with both the roughing operation and the finishing operation of online cnc machining service in order to be successful at their job. These two aspects of online cnc machining service are the roughing operation and the finishing operation, respectively. absolutely nothing interesting about it

The process of boring involves removing excess material from a hole that has been cut into a workpiece. This is done after the hole has been drilled. This process is commonly referred to as being boring. Boring is a process that is only useful after a hole has been drilled into the material that will be worked on before it can be used. Before boring can be used, however, the material must first have the hole drilled into it. The method requires a significant amount of time and can ordinarily only be applied to projects of a moderate or lower level of complexity. The diameter of the hole is used as the criterion for determining the maximum bit size that can be accommodated by the tapping tool. The maximum bit size is determined by the diameter of the hole. The diameter of the hole can be measured to provide an answer to this question. After the machine has been prepared, the workpiece is positioned so that it is facing a faceplate, and the machine is then given a slow rotational speed. Knurling not only gives the machined part a more appealing appearance from an aesthetic standpoint, but it also makes it simpler to grasp the part when it is necessary to do so. This is because knurling adds ridges to the surface of the part in a spiral pattern.

6. This step is carried out while the piece of work is being rotated. The size of the drill bit that is utilized in the process of carrying out the procedure will serve as the determining factor in determining the size of the hole that is produced as a result of the procedure. While the workpiece is being rotated in a faceplate or chuck on the lathe, accurate positioning of the workpiece can be achieved by utilizing either a lathe tool holder or a tailstock drill holder. Both of these holders can be attached to the lathe's tailstock. In its most basic form, the process known as "reaming" can be understood as "sizing."A very low rotational speed is applied to the workpiece while it is being turned on a spindle that is attached to the tailstock. This keeps the reamer in place. Leaving a trail behind oneself

Parting is a type of online cnc machining service operation that is used to cut a workpiece, but this can only be done after the workpiece has been properly machined to the required dimensions and shape. In other words, parting is the only way to cut a workpiece after it has been machined. The term "parting" can also be written as "parting off."The cutting tool will, at some point in the course of carrying out the procedure, make its way into the core of the workpiece.

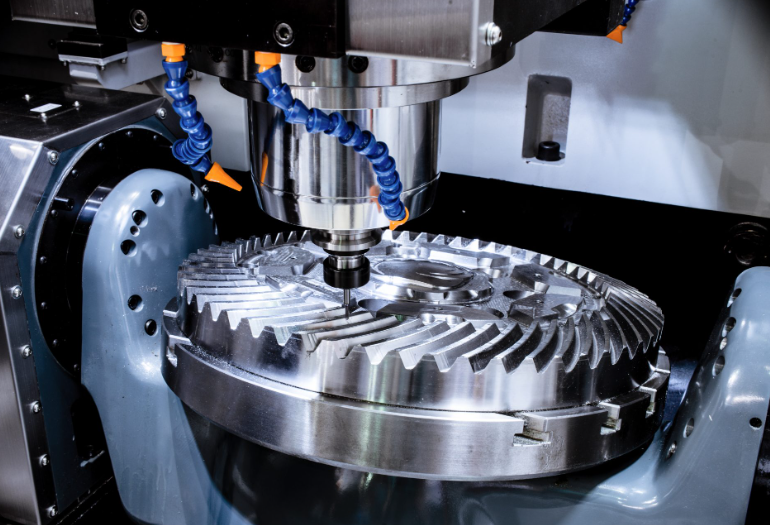

CNC, which stands for computer numeric control, is a manufacturing technique that makes use of online cnc machining service as one of its processes. During this procedure, (in most cases) bars of material are kept in a chuck and rotated while they are being processed. The use of a cutting tool will be continued to be utilized in order to remove additional material in order to achieve the desired and final shape. This process will carry on until the shape has been completely formed.

How exactly does one go about online cnc machining service something, and what are the steps involved in doing so?

-

Grooving is the process of that results in a cut that is extremely shallow and precise

-

This process is known as turning

-

CNC lathes are being utilized in order to carry out the particular machining process that is currently being performed

-

The reamer is not used in the process of making the hole; rather, it is added to the procedure after the hole has already been created

-

This is because the reamer is too large to fit through the hole

Determine the millimeter-based length measurement for the length of the cut using the calculator. Millimeters are the unit of measurement. This length of the cut is equal to the job length plus the tool over travel plus the tool approach. This length of the cut is equal to the job length plus the tool over travel plus the tool approach. This feed value can be calculated by taking the total number of teeth and dividing that number by the amount of feed that is given per tooth. This will result in the value of the feed.