Custom plastic products manufacturers are essential players in the production and delivery of high-quality plastic goods. As the demand for custom plastic products continues to rise, it's crucial for manufacturers to stay ahead of the game. Here are some essential tips for custom plastic products manufacturers to excel in their field.

Embrace Technology

In the fast-paced world of manufacturing, staying up-to-date with the late technological advancements is vital. Custom plastic products manufacturers should invest in advanced machinery and equipment to improve production efficiency and product quality. Automation and computer-aided design (CAD) software can streamline the manufacturing process, reduce errors, and enhance customization options.

Focus on Quality Control

Custom plastic products must meet stringent quality standards to ensure customer satisfaction. Implementing a rigorous quality control system is crucial for manufacturers. Regular inspections, testing, and monitoring of production processes will help identify and rectify any issues before the final products are delivered. Consistently providing high-quality products will build a solid reputation and foster long-term customer relationships.

Maintain Sustainable Practices

With growing environmental concerns, consumers are increasingly conscious of the ecological impact of their purchases. Custom plastic products manufacturers should adopt sustainable practices to reduce waste and reduce their carbon footprint. This includes using recycled materials, implementing energy-efficient manufacturing processes, and promoting recycling and reusability of their products. Showcasing a commitment to sustainability will attract environmentally-conscious customers and distinguish manufacturers from their competitors.

Offer Customization Options

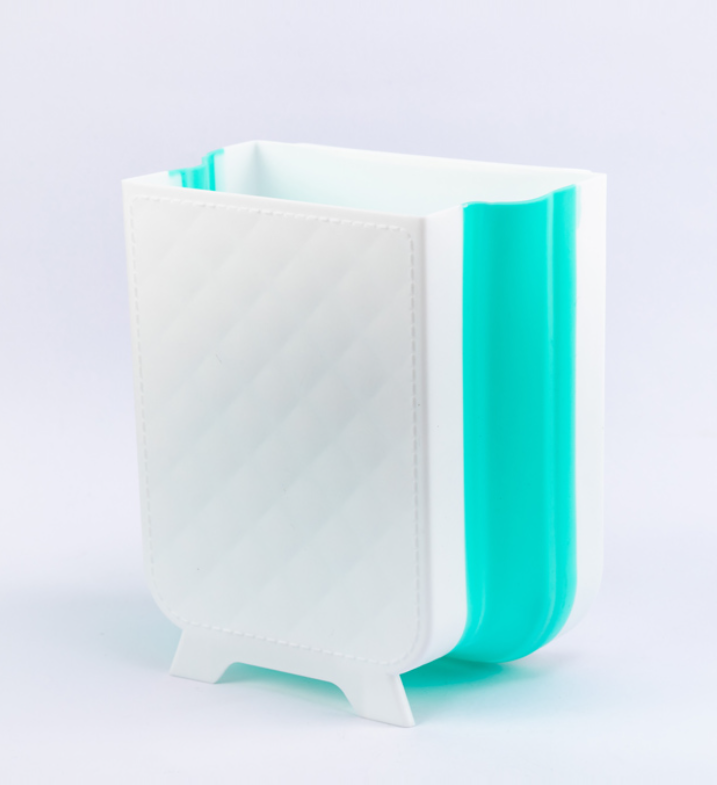

Custom plastic products are highly sought after because of their unique features that cater to specific customer needs. Manufacturers should be flexible and offer a wide range of customization options. This can include various colors, sizes, shapes, and branding opportunities. Additionally, providing design assistance and prototyping services can help customers visualize the end product and make informed decisions. The ability to deliver tailored solutions will ensure customer satisfaction and foster loyalty.

Be Responsive and Communicative

Effective communication is key to successful collaborations between custom plastic products manufacturers and their customers. Manufacturers should establish clear lines of communication, providing regular updates on the progress of orders and addressing any concerns promptly. Being responsive to customer inquiries, offering technical support, and providing post-sale assistance will build trust and establish a reputation for excellent customer service.

Continuous Improvement

Custom plastic products manufacturers must be committed continuous improvement. Regularly evaluating and refining processes, investing in research and development, and staying updated on industry trends lead to innovation and growth. Manufacturers should aim to learn from their experiences and adapt their strategies accordingly to remain successful in a competitive.

Focus on Sustainability

In today's environmentally conscious world, sustainability is a key factor for success in any industry, including custom plastic products manufacturing. Manufacturers can eco-friendly practices such as using recycled materials, reducing energy consumption, and implementing waste management strategies. A focus on sustainability not only benefits the environment but also attracts environmentally conscious clients.

In conclusion, custom plastic products manufacturers must embrace technology, implement quality control systems, maintain sustainable practices, offer customization options, and prioritize effective communication to excel in their industry. By following these tips, manufacturers can differentiate themselves in a rapidly evolving market, meet customer expectations, and drive long-term success.