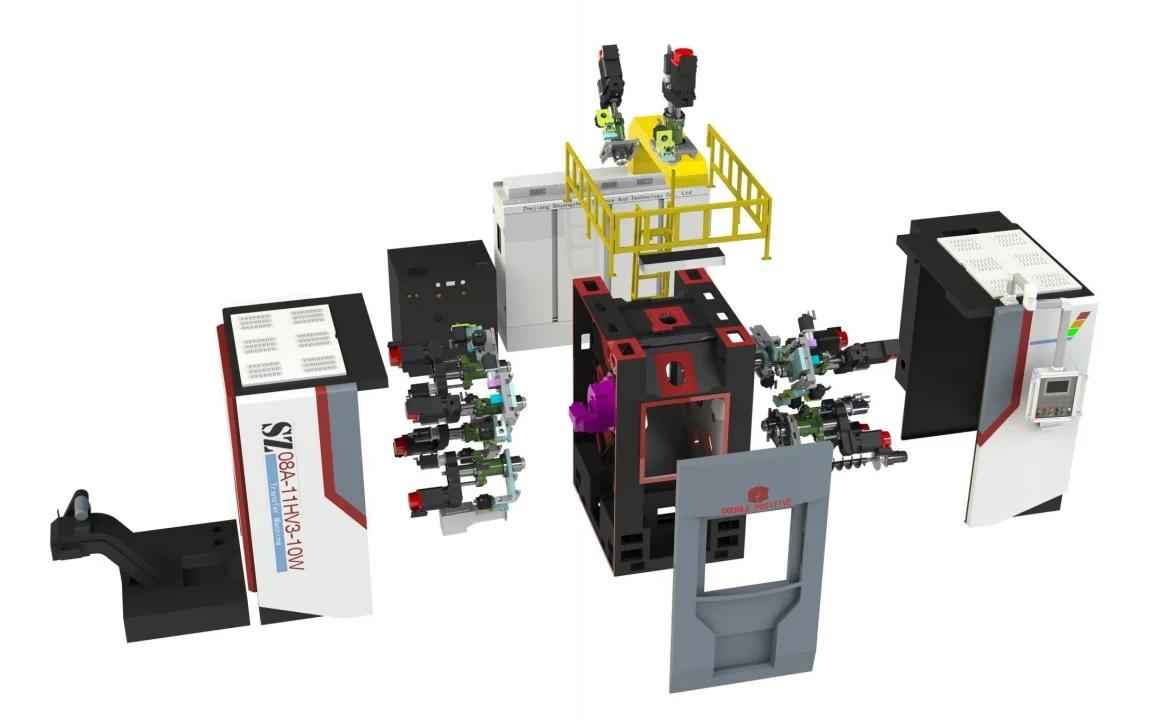

Full Automatic Hydraulic Machine(CJK0635) adopts horizontal flat bed structure, bed, bed, bed saddle, bed legs and other basic parts are cast by resin sand, artificial aging treatment, the whole machine stability is good. Medium frequency quenching of the bed guide rail, the combination surface of the bed saddle and slide guide rail adopts "plastering" treatment, and the moving parts can achieve micro-feed to prevent crawling.

Lubrication system occupies a very important position in CNC machine tools, and its design, debugging and maintenance play a very important role in improving the machining accuracy of CNC machine tools and extending the service life of machine tools. The lubrication of sliding pairs such as guide rail and screw of modern machine tools is basically a centralized lubrication system in CNC machining centers.

Full Automatic Hydraulic Machine(CJK0635) Monitoring the working state of the lubrication system:

In addition to the lack of oil supply due to oil consumption and too little oil tank in the lubrication system, the common faults include the failure of the oil pump, the blockage of the oil supply pipeline, the abnormal work of the shunt, and the serious oil leakage. Therefore, the following detection device is set up in the lubrication system to monitor the working state of the lubrication pump to avoid the machine tool working in the state of oil shortage, affecting the performance and service life of the CNC machine tool.

1, overload detection in the power supply circuit of the lubrication pump use overload protection elements, and its thermal overload contact as the input signal of the PMC system, once the lubrication pump overload, the PMC system can detect and deal with, so that the machine tool immediately stop running.

2. The oil level detection lubricating oil is a consumable, so after the Full Automatic Hydraulic Machine(CJK0635) works for a period of time, the lubricating oil in the lubricating pump tank will gradually decrease. If the operator does not add the oil in time, when the oil in the tank reaches the low oil level, the oil level detection switch will act immediately, and the signal will be transmitted to the PMC system for processing.

3, the pressure detection machine adopts a progressive centralized lubrication system, as long as the system works normally, each lubrication point can ensure that the predetermined lubricant. Once the lubrication pump itself is not working normally, failure, or there is a blockage of the oil supply pipeline in the oil supply circuit, oil leakage, etc., the pressure in the system will be abnormal.

According to this feature, the pressure detection switch is installed at the outlet of the lubrication pump in the design, and the switch signal is input to the PMC system, after each lubrication pump work, check the pressure in the system, once found abnormal, immediately stop the work of the Full Automatic Hydraulic Machine(CJK0635). And generate alarm signal.

Full Automatic Hydraulic Machine(CJK0635) https://www.zjshuangzheng.com/Full-Automatic-Hydraulic-Machine-CJK0635.html